product (array):

id = '15540'

productMainId = '5216'

ean = null

vendorProductId = '097-004848-00015'

manufacturerProductId = 'A102593 WP 380'

manufacturerId = null

productSearchId = null

stock = '15'

stockBehaviour = '1'

stockView = '0'

stockViewText = null

dateCreated = '2024-03-19 15:28:46'

dateModified = null

public = '1'

active = '1'

deleted = '0'

packagingAmount = '1500'

packagingUnit = 'sa'

priceAmount = '100'

priceUnit = 'kg'

forcePrice = '0'

priority = '0'

validFrom = null

validTo = null

hidden = '0'

notSellable = '0'

externalId = '143094'

productText (array):

id = '23161'

productId = '15540'

languageId = '38'

nameShort = 'FW CS 1 63 DC'

name = 'FW CS 1 63 DC 15kg'

description = '<ul class="description_list"><li class="first-item">Molten neutral welding flux</li><li>Suitable for high-alloy stainless steels, Ni-based alloys and low-alloy steels</li><li>Especially crack-resistant in connection with similar or over-alloyed wire electrodes (solid or flux cored wire)</li><li>For welding low-alloy, creep-resistant steels and high-alloy Cr, CrNi and CrNiMo steels</li><li>Also suitable for joint welding of nickel alloys</li><li>Can be used for surfacing and dissimilar joints</li><li>Self-dissolving slag</li><li>Good seam deformation capacity</li><li>Particularly crack-resistant in conjunction with similar or over-alloyed wire electrodes (solid or flux-cored wire types)</li><li class="last-item">Pipeline, container and boiler construction</li></ul>'

descriptionShort = '<p>Molten neutral welding flux</p><p>Suitable for high-alloy stainless steels, Ni-based alloys and low-alloy steels</p>'

deliveryScope = null

isSellable = true

productStock (object: ProductStockModel):

(private) redLimit = null

(private) yellowLimit = null

(private) product (object: ProductEntity):

(private) id = '15540'

(private) productMainId = '5216'

(private) ean = null

(private) vendorProductId = '097-004848-00015'

(private) manufacturerProductId = 'A102593 WP 380'

(private) manufacturerId = null

(private) productSearchId = null

(private) stock = '15'

(private) stockBehaviour = '1'

(private) stockView = '0'

(private) stockViewText = null

(private) dateCreated = '2024-03-19 15:28:46'

(private) dateModified = null

(private) public = '1'

(private) active = '1'

(private) deleted = '0'

(private) packagingAmount = '1500'

(private) packagingUnit = 'sa'

(private) priceAmount = '100'

(private) priceUnit = 'kg'

(private) forcePrice = '0'

(private) priority = '0'

(private) validFrom = null

(private) validTo = null

(private) hidden = '0'

(private) notSellable = '0'

(private) externalId = '143094'

(private) se�oldInstance = null

(private) behaviour = null

(private) showOption = null

(private) showOptionText = null

(private) stock = null

productPrice = 164.69999999999999

productTax = '19'

productPriceGross = 195.99299999999999

productCurrency = 0

productPriceForAmount = 164.69999999999999

manufacturer (array):

name = ''

productQuantityUnit = 'sa'

mime (array):

0 (object: MimeEntity):

(private) id = '41989'

(private) parentId = null

(private) uri = 'IM0005458.jpg'

(private) type = 'Produktbild'

(private) usage = null

(private) mimeType = 'image/jpeg'

(private) width = '800'

(private) height = '600'

(private) size = null

(private) version = null

(private) externalId = '0A448889'

(private) languageId = null

(private) yBase�oldInstance = null

1 (object: MimeEntity):

(private) id = '18707'

(private) parentId = null

(private) uri = 'IM0001988thszw.jpg'

(private) type = 'adInfo'

(private) usage = null

(private) mimeType = 'image/jpeg'

(private) width = '80'

(private) height = '80'

(private) size = null

(private) version = null

(private) externalId = '0A42838thszw'

(private) languageId = null

(private) yBase�oldInstance = null

attributes (array):

62 (array):

name = 'DINnorm'

value = 'DIN EN ISO 14174 (stainless steels) - S F CS 2 5742 DC'

unit = null

sort = '10'

public = '1'

isFilter = '1'

attributeId = '62'

productAttributeId = '480517435'

attributeValueId = '12543406'

languageId = null

588 (array):

name = 'Hauptschweißverfahren'

value = 'drive'

unit = null

sort = '10'

public = '1'

isFilter = '1'

attributeId = '588'

productAttributeId = '480517437'

attributeValueId = '7984097'

languageId = null

590 (array):

name = 'Schweißverfahren'

value = 'AC | DC- | DC+'

unit = null

sort = '20'

public = '1'

isFilter = '1'

attributeId = '590'

productAttributeId = '480517438'

attributeValueId = '12350053'

languageId = null

productPriceCollection (array):

0 (array):

type = 'date'

quantity = '0'

validFrom = '2023-07-27 00:00:00'

validTo = '2024-05-01 00:00:00'

price = 164.69999999999999

tax = 19.0

taxTotal = 31.292999999999996

total = 195.99299999999999

1 (array):

type = 'date'

quantity = '0'

validFrom = '2024-05-01 00:00:00'

validTo = null

price = 173.69999999999999

tax = 19.0

taxTotal = 33.003

total = 206.70299999999997

2 (array):

type = 'date'

quantity = '0'

validFrom = '2023-07-27 00:00:00'

validTo = '2024-05-01 00:00:00'

price = 148.19999999999999

tax = 19.0

taxTotal = 28.157999999999998

total = 176.35799999999998

3 (array):

type = 'date'

quantity = '0'

validFrom = '2024-05-01 00:00:00'

validTo = null

price = 156.30000000000001

tax = 19.0

taxTotal = 29.697000000000003

total = 185.99700000000001

productName = 'FW CS 1 63 DC'

produktbezeichnung = 'Melted, non-Cr-compensated welding flux'

price = 164.69999999999999

currencySign = '€'

ewmPriceSurcharge = '0,00 €'

recommendedAccessories (array):

0 = null

hasSpareParts = '0'

ewmVariants (array):

0 (array):

productPrice = 164.69999999999999

productPriceGross = 195.99299999999999

id = '15540'

ewmLowestPriceGross = 195.99299999999999

ewmLowestPrice = 164.69999999999999

ewmLowestPricePackagingUnit = 'sa'

ewmLowestPricePackagingAmount = '1500'

listprice = '164.7'

ewmRabattgruppe = 'Z13'

ewmQuantityPriceCollection (array):

0 (array):

quantity = '0'

price = 164.69999999999999

tax = '19'

taxTotal = 31.292999999999996

total = 195.99299999999999

ewmStock = '15'

ewmStockColor = '<span class="green"></span> in stock'

vmMime (array):

0 (object: MimeEntity):

(private) id = '41989'

(private) parentId = null

(private) uri = 'IM0005458.jpg'

(private) type = 'Produktbild'

(private) usage = null

(private) mimeType = 'image/jpeg'

(private) width = '800'

(private) height = '600'

(private) size = null

(private) version = null

(private) externalId = '0A448889'

(private) languageId = null

(private) yBase�oldInstance = null

1 (object: MimeEntity):

(private) id = '18707'

(private) parentId = null

(private) uri = 'IM0001988thszw.jpg'

(private) type = 'adInfo'

(private) usage = null

(private) mimeType = 'image/jpeg'

(private) width = '80'

(private) height = '80'

(private) size = null

(private) version = null

(private) externalId = '0A42838thszw'

(private) languageId = null

(private) yBase�oldInstance = null

blocks (array):

PT_TD_lang (array):

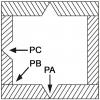

0 = '<table class="detail_table"><tbody><tr><td class="td1">Standards</td><td>DIN EN ISO 14174 (stainless steels) - S F CS 2 5742 DC</td></tr><tr><td class="td1"/><td>DIN EN ISO 14174 (unalloyed/low-alloy steels) - S F CS 1 63 DC</td></tr><tr><td class="td1">Welding positions</td><td>PA / PB / PC</td></tr><tr><td class="td1">Polarity</td><td>AC | DC- | DC+</td></tr><tr><td class="td1">Chemical analysis (in %)</td><td>SiO<sub>2</sub> : 30 %Al<sub>2</sub>O<sub>3</sub> + MnO : 5 %CaO + MgO : 35 %CaF<sub>2</sub> : 20 %</td></tr><tr><td class="td1">Grain size</td><td>DIN EN ISO 14174 - 1 - 16</td></tr><tr><td class="td1">Base materials</td><td>Creep-resistant CrMo steels such as 12 CrMo 19 5/A378 gr. 5 or X 20 CrMoWV 12 1/A351 for boiler, container and pipe construction / Martensitic (soft martensite) and ferritic Cr(NiMo) steels in acc. w. DIN EN 10088 and austenitic CrNi(Mo) steels in acc. w. DIN EN 10088 / Low-temperature tough and heat-resisting high-alloy CrNi(Mo) steels, dissimilar joints and nickel-base alloys</td></tr></tbody></table>'

PT_TD_Vergl (array):

0 = '{"Standards": "DIN EN ISO 14174 (stainless steels) - S F CS 2 5742 DC","": "DIN EN ISO 14174 (unalloyed/low-alloy steels) - S F CS 1 63 DC","Welding positions": "PA / PB / PC","Polarity": "AC | DC- | DC+","Chemical analysis (in %)": "SiO","Grain size": "DIN EN ISO 14174 - 1 - 16","Base materials": "Creep-resistant CrMo steels such as 12 CrMo 19 5/A378 gr. 5 or X 20 CrMoWV 12 1/A351 for boiler, container and pipe construction / Martensitic (soft martensite) and ferritic Cr(NiMo) steels in acc. w. DIN EN 10088 and austenitic CrNi(Mo) steels in acc. w. DIN EN 10088 / Low-temperature tough and heat-resisting high-alloy CrNi(Mo) steels, dissimilar joints and nickel-base alloys"}'

innoWeld (array):

0 = '<p/>'

Einsatzgebiete (array):

0 = null

vmAttributes (array):

62 (array):

name = 'DINnorm'

unit = null

values (array):

0 = 'DIN EN ISO 14174 (stainless steels) - S F CS 2 5742 DC'

588 (array):

name = 'Hauptschweißverfahren'

unit = null

values (array):

0 = 'drive'

590 (array):

name = 'Schweißverfahren'

unit = null

values (array):

0 = 'AC | DC- | DC+'

vmCharacteristics (array):

customFields (array):